Compare the cost of owning a canning system vs. hiring a mobile canner using our automated canning calculator.

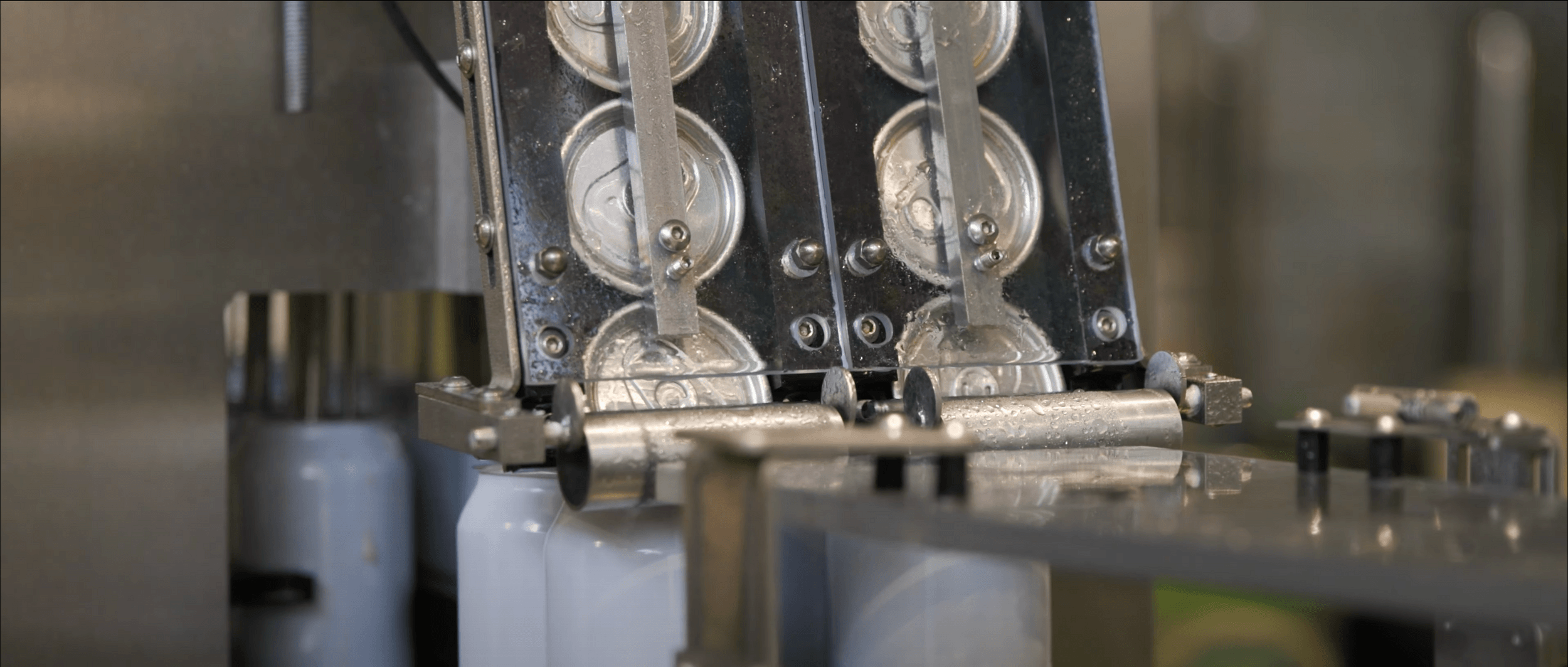

See Alpha’s Canning Equipment in Action

Videos of our canning lines in breweries around the world:

10 million cans with Alpha

Big Grove Brewery in Iowa City, Iowa recently hit 10 million cans with our Gen1 canning line.

Launchpad Brewing in Aurora, Colorado

Owner/Founder/Brewmaster David Levesque talks about his favorite features on the Alpha BC2.

Behemoth Brewery in Auckland, New Zealand

Distributed by FB Propak, Behemoth’s 24 cans per minute Alpha canning line, Alpha brewhouse and Alpha fermentation units work together to make this awesome brewery.